Paint Stripping

We are expanding our services to include thermal paint stripping by Pyrox!

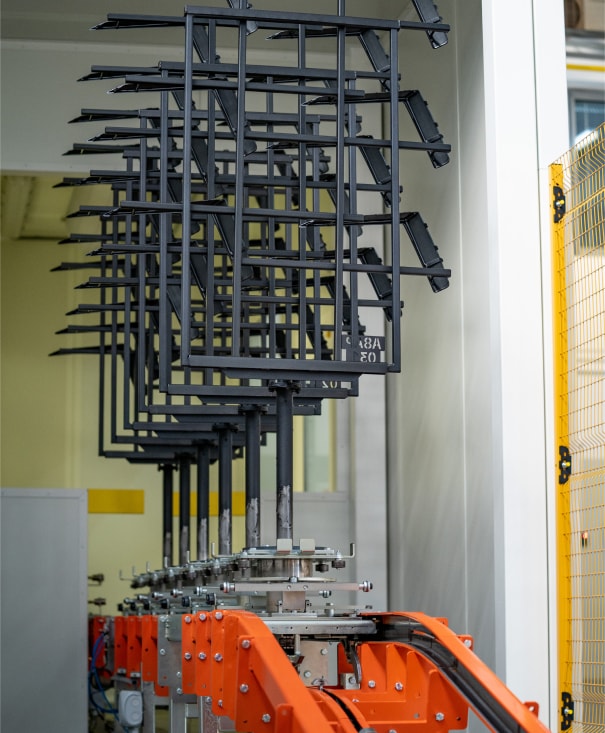

We at NEONLAK proudly announce that in the year 2025, we are going to expand our services to include innovative thermal paint stripping by Pyrox. This cutting edge technology allows us to quickly and ecologically remove old paint and surface treatment from various materials. Thanks to thermal paint stripping, we can offer our customers a faster and cleaner process, which minimises its impact on the environment and ensures a high quality finish.

Pyrox thermal paint stripping is ideal for industrial application, where it is necessary to remove old layers quickly and effectively. This process takes place at an elevated temperature in an low-oxygen environment, where heat is evenly distributed. Components are heated to between 300°C and 500°C for a duration between 4 and 12 hours. During pyrolysis, paint (or other organic film) is reduced to ash without impacting the mechanical characteristics or measurements of treated parts. Not only is this method eco-friendly, it is also economically advantageous, which makes it the perfect choice for our customers. Join us and tak advantage of the benefits of this modern technology, which pushes the limits of quality and efficiency in the surface treatment industry.

Uses: e.g. cleaning of lacquering hinges, frames, hooks, grates, removal of unsatisfactory or old coating from parts, various redos

We are also preparing the new Laser Paint Stripping service for YOU

Our new laser paint stripping service brings a revolutionary method for removing paint from various materials like metal, concrete or wood. This mobile device allows us to arrive directly to your doorstep, which means that you do not have to transport components anywhere. Our mobile device is designed for flexibility and convenience, which allows us to bring our services to the customer. If you need to strip metal parts or wood surfaces, our laser technology is the ideal choice.

Parameters

- Internal dimensions: width 2500 mm, depth 5000 mm, height 2500 mm

- Volume: 25,0 m³

- Furnace temperature: up to 450°C

- Secondary burn chamber temperature: 850°C

- Furnace burner capacity: 240 kW

- Secondary burn capacity: 360 kW

- Gas consumption (natural gas): 60 kW/h maximum, 26-37 kWh average

Benefits of our service

Speed

Laser stripping is quick and effective, which saves your time.

Precision

Laser enables precise removal of paint layers without causing damage to the base material.

Effectivity

Our technology is highly effective and eco-friendly.