Industrial Painting

For the needs of our clients, NEONLAK has a combination of innovative robotic and manual working lines at the ready.

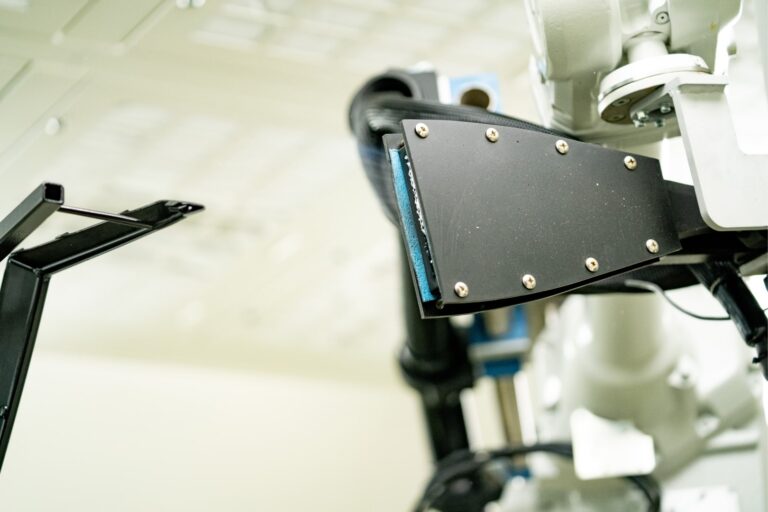

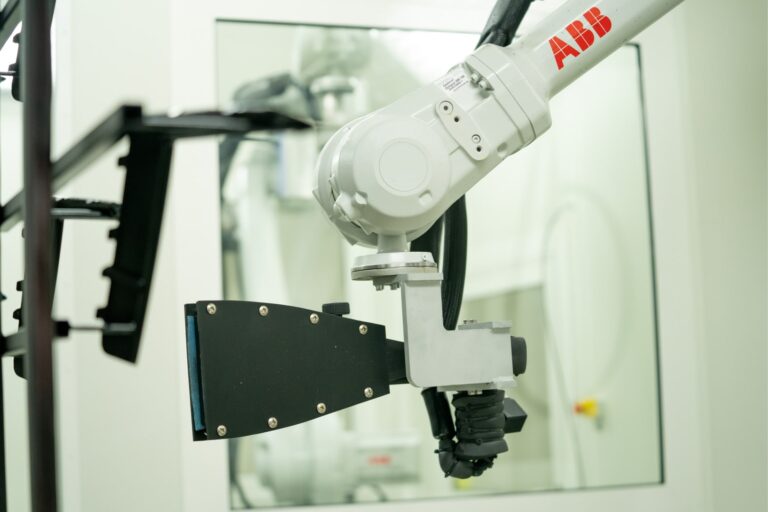

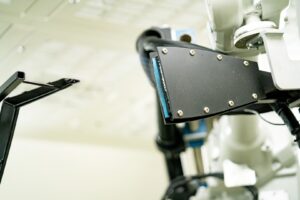

Automated Painting Line

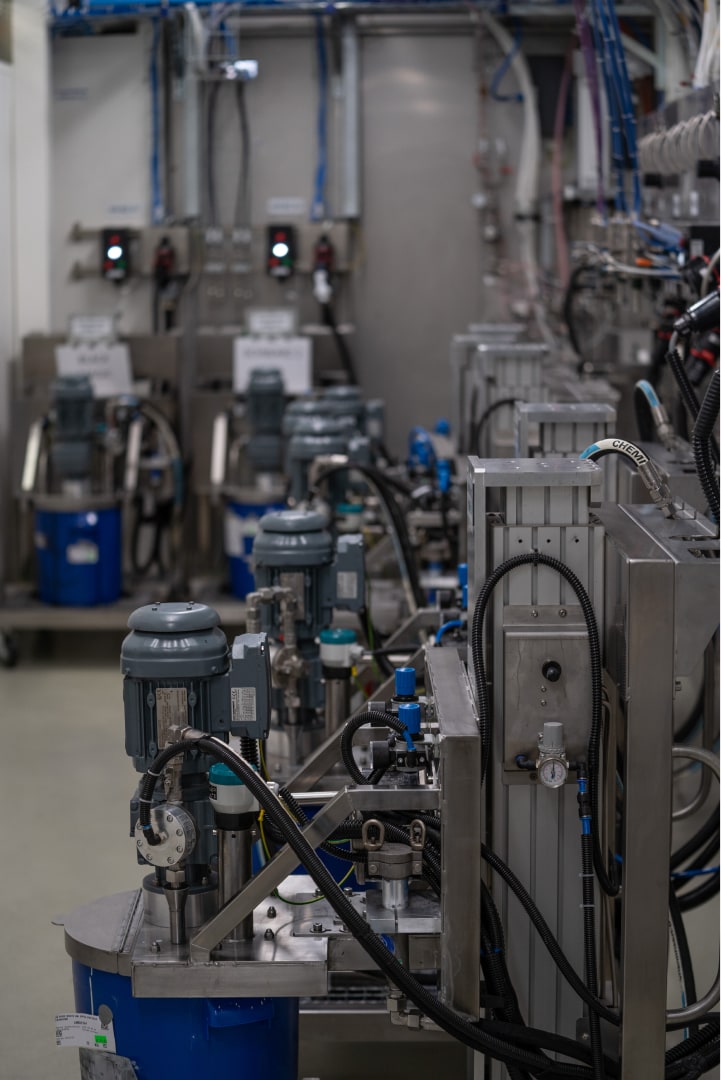

The innovative "PLAZY" automated coating line takes care of the coating of plastic. It is equipped mainly for high-volume projects. The production is built on the latest commercially available technologies in robotic painting and places great emphasis on ecology.

The actual painting technology has been supplemented by a VOC thermal liquidation device, cold sources for the airflow intake system, and a sophisticated compressor room. The integrated control unit and its functionality is designed in accordance with the latest industrial automation trends, as well as the "Industry 4.0" requirements.

The automated painting line observes all requirements for the painting of interior and exterior parts for the automotive industry and it also emphasizes ecology.

PARAMETERS

- 4000 m² area

- the latest ABB robots

- robotic part cleaning and degreasing using CO₂

- robotic flaming

- robotic application of water- or solvent-soluble materials

- robotic application of solvents to the outer layer

- Power & Free conveyor system

- pigging technology of robot filling

- software-based monitoring of processes and paint line settings

- paint line capacity: 2.5 million+ /year depending on the size and design of parts

Benefits of robotic painting at NEONLAK

- material loss minimisation (thanks to pigging technology and short distribution of painging materials)

- efficient use of capacities, flexible switching of projects (thanks to Power & Free conveyors)

- digitalization, online production control and monitoring (MES system)

- modern warehouses, sufficient storing capacities

- green politics (up to 30% of electric energy used by the automated production line comes from renewable resources)

- effective use of know-how in industrial painting; effective use of staff expertise for unique solutions and fulfilment of clients‘ original requirements

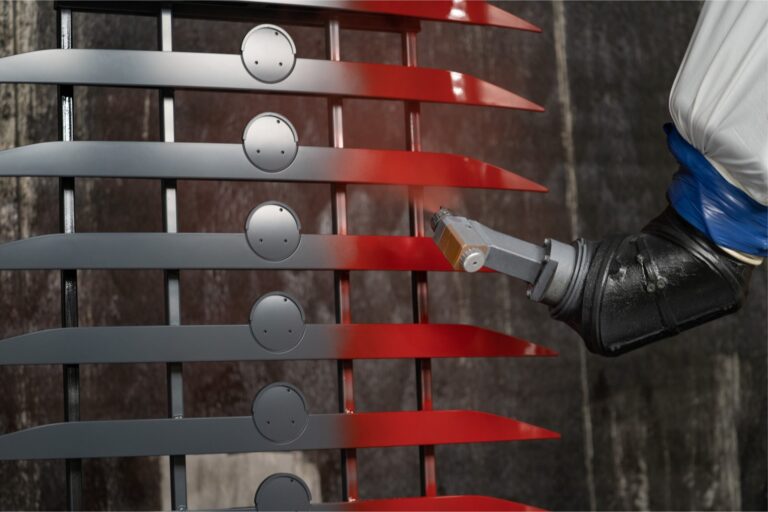

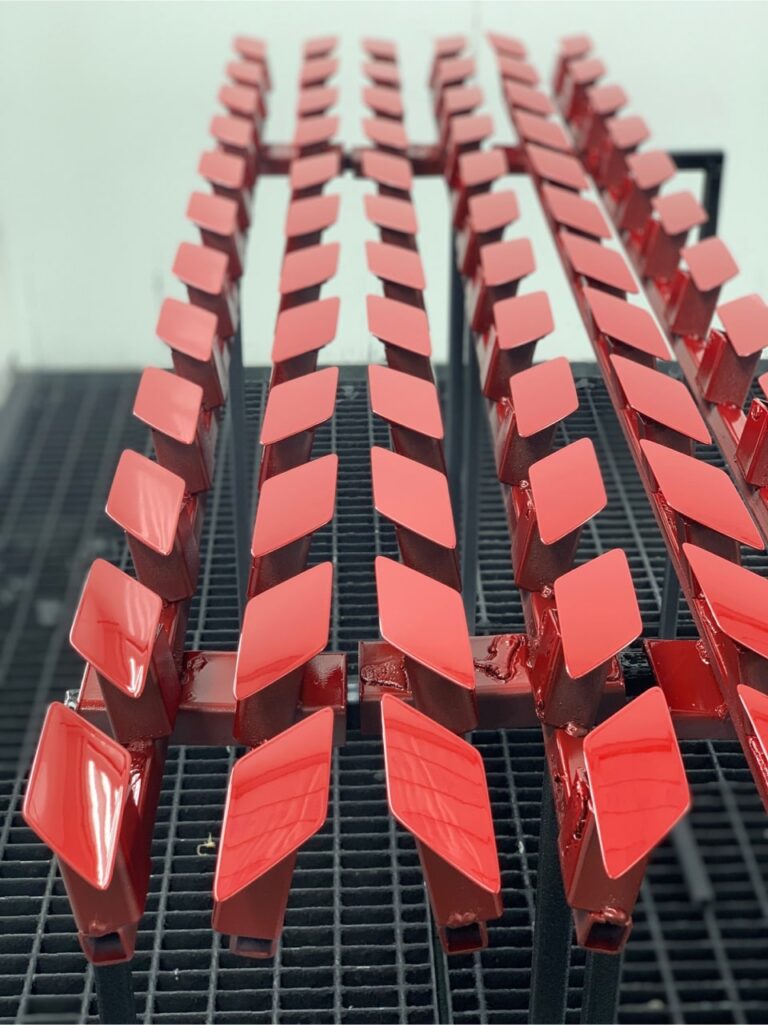

Manual paint shop

The „PTÁCKÁ“ manual paint shop facility provides painting of all materials: plastic/metal/laminate/wood and simultaneously processes required quality and quantities of: intial check – part preparation – painting in USI Italia paint booths – finishing treatment – outgoing check for over 250 thousand parts monthly.

Before the actual painting, parts undergo preparation in order to remove mechanical impurities, grease stains, lubricant residue, and so reach required material adhesion, which is mainly secured by plastic substrate and its processing by the supplier. Some materials, especially polypropylenes, must undergo scorching in order to ensure required adhesion.

Wet application of coating material is performed manually, using DeVilBiss a SATApneumatic spray guns. In the paint booth takes place the coating of various bodywork parts or vehicle components. Water-soluble paints, solvent based paints, two-component paints, acrylic paints, primers, paint with hardener.

PARAMETERS

- 2800 m² area

- 6 paint booths

- the possibility of painting of all materials: plastic / metal / laminate / wood

- painting with both solvent materials and water-soluble materials

- great component size variability

- booth inner dimensions 7m × 4m

- the possibility of small-scale and comission based projects